Solutions

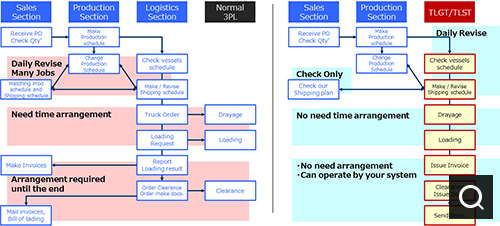

1. Shipping Arrangements

- The way we perform shipping arrangements is different than other 3PL companies. In the case of other 3PL companies, the shipper needs to arrange schedules and provide instructions for shipping to 3PL companies step by step. With us, the shipper just provides production schedules and shipping orders to us. We check on the latest schedules available day by day and update shipping schedules on our side. We can also arrange packing schedules, inland transportation, and the shipping of documents in the place of the customer. That way, customers can focus on their main businesses of production and sales. - In addition, if a customer is able to accept our usage of their system, we can operate or update data in line with your requirements.

2. Logistics Optimization

- By calculating optimal loading methods and packing methods on case-by-case basis, you can minimize wasted space as much as possible. This means that the customer can enjoy cost reductions, high quantities, and quality. - In line with customers requirements, we can unitize cargo for higher quality and reductions of time and labor.

3. Raw Material Warehouse Service

- We provide raw materials to production lines in a timely manner in accordance with customer requirements. Also, we can respond to special requirements and deliver cargo in a way desired by the production line.

4. Logistics Consulting

We consider the best solution from the customer's point of view.

Example 1 : - Customer A increased their number of warehouses as their volume of production increased. We reviewed and analyzed the required warehouse specifications, future demand forecasts, and optimal solutions from the viewpoints of cost and quality, and proposed the best warehouse positioning for the situation. As a result, Customer A was able to secure enough space and reduce wasteful transportation.

Example 2 : - The inventory of Customer B had increased as a result of the ocean market confusion arising in 2020-2021. Customer B wanted to increase storage capacity with same space, so we investigated their cargo storage situation and proposed the changing of pallet sizes for an optimized setup, and provided a layout catering to the new pallet sizes. As a result, customer B became able to store more inventory within the same amount of space.

5. Quality Improvement

When it comes to handling the precious products of our customers, we are aiming to improve quality on a daily basis and carry out the following activities: - Cycle forklift training - Mind training for all employees to improve the quality of cycles - Education by dedicated team - Safety and quality patrols - Quality control meetings (both internally and with customers)